Why are apparel supply chains so complicated?

How many steps does it take for a piece of clothing to reach a store?

At first glance, it seems simple—brand, vendor, factory.

But in reality, it’s far more complex. And that complexity affects the price.

The Brand: The Visionary Behind the Product

The brand doesn’t make the clothes—it plans them.

It decides what clothes to produce and takes charge of marketing.

Everything consumers see originates from the brand.

The Vendor: The Bridge Between Brand and Factory

Vendors handle execution.

They receive the plan from the brand, procure materials, and place orders with factories.

They are also responsible for deadlines and quality—coordinators in the truest sense.

The Factory: Where Clothes Are Actually Made

The factory is closest to the action.

Cutting, sewing, packing—all happen here.

The clothes we wear come from this stage.

But Why So Complicated?

It would be great if the supply chain ended at three steps—but reality isn’t so kind.

Multi-layered Structure

Brand → Vendor → Factory.

Add in subcontractors, suppliers, and approval processes, and

communication slows down, and decisions are delayed.

Country-Specific Roles

Fabric from China, sewing in Vietnam, distribution in Europe.

One item of clothing might cross 3 to 4 borders.

Different languages, time zones, laws—it’s a coordination nightmare.

Too Many Stakeholders

It’s not just brands, vendors, and factories.

Fabric mills, logistics firms, inspection agencies—all involved.

Everyone has different priorities, leading to conflict and delays.

How Does This Complexity of the Apparel Supply Chain Affect Pricing?

Complex supply chains ultimately mean higher costs.

The more steps involved, the higher the final price.

Costs Keep Adding Up

Vendor commissions, factory overhead, logistics fees, quality inspection costs…

All of these stack up and impact the final price tag.

Delays Mean Extra Costs

If information is late or decisions are slow, deadlines are missed.

Then comes emergency production and shipping—everything costs more.

Quality Control Gets Harder

Multiple factories = inconsistent quality standards.

Defects lead to returns and rework—more hidden costs.

Risk Management Isn’t Free

To prepare for exchange rate fluctuations, raw material costs, and political risks,

companies stockpile inventory and buy insurance.

These costs are reflected in the consumer price.

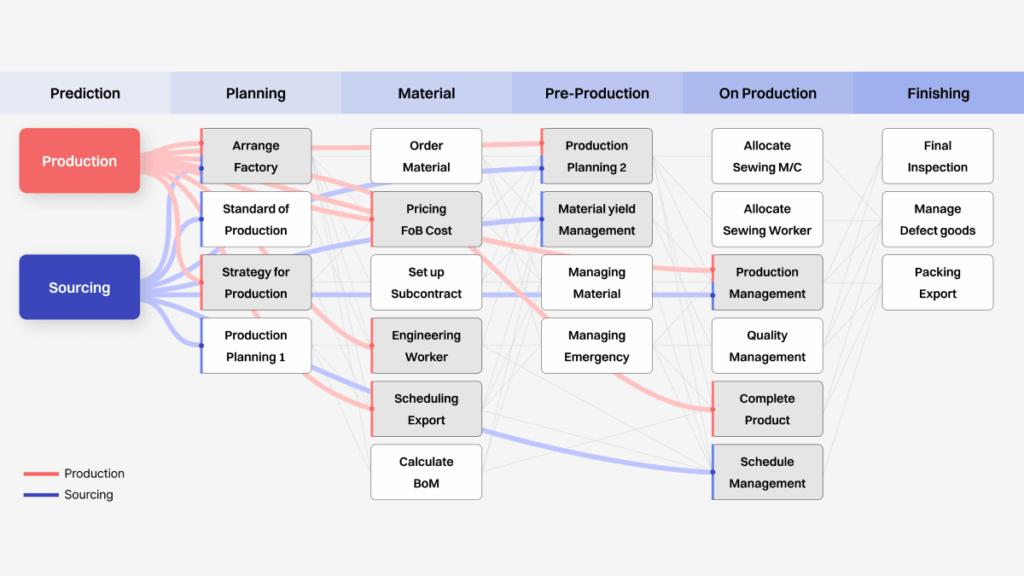

Rethinking the Apparel Supply Chain

A complex supply chain leads to complex pricing.

That’s why today’s brands aim to digitize and streamline operations.

Managing flows in real-time and cutting out inefficiencies—

that’s the key to stronger price competitiveness.

➡️ Coming Next

We at SIJE are on a mission to solve the root problems of complex supply chains and shifting production bases.

In the next post, we’ll explain how SIJE is turning this mission into reality.

References

- Smith, J. (2019). Complexity in Apparel Supply Chains. Journal of Fashion Technology, 12(3), 45-60.

- Lee, H. (2020). Global Supply Chain Management in the Apparel Industry. International Journal of Advanced Manufacturing, 15(2), 123-135.

- Kim, S. (2021). Impact of Supply Chain Complexity on Pricing. Textile Research Journal, 18(4), 89-102.

- https://www.mckinsey.com/industries/retail/our-insights/apparel-brands-finally-shift-to-deeper-supplier-relationships